What is Oil Canning?

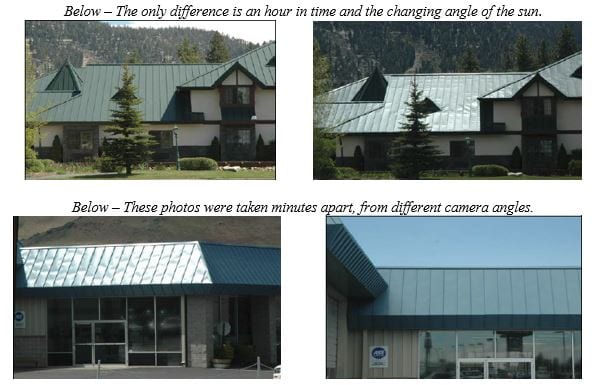

Oil canning can be defined as visible waviness in the flat areas of metal roofing and metal wall panels. In technical terms, oil canning is referred to as elastic buckling (more commonly known as “stress wrinkling”). It can occur in any type of metal panels; steel, aluminum, zinc or copper. For purpose here, all four terms shall be considered synonymous: Waviness, elastic buckling, stress wrinkling, ballooning and oil canning. The degree of waviness can be difficult to measure but may be apparent especially under specific lighting conditions. Generally, the period and amplitude of the wave will become more pronounced as the panel width increases (flat portion of the panel) and/or the panel thickness decreases. Reflected light may make the oil canning more prominent at certain times of day.

Conditions such as the time of year, the viewing angle, and the angle at which sunlight strikes the panel may also have an impact on the ability to discern oil canning. The eye perceives the reflection of light, and when the reflective surface is irregular the reflected light is also irregular making it more perceptible. If oil canning is present, it is usually apparent at the time of construction

However, oil canning may become more (or less) apparent over an extended period of time for a variety of reasons. Oil canning can be an unintentional byproduct of the fabrication process and mill producers’ tolerances. Panels with canning differ from panels intentionally formed with a corrugated, ribbed, or fluted design and narrower flat sections intended to provide greater bending strength.

What Causes Oil Canning?

Oil canning is caused by differential stresses within the metal itself. As the metal tries to relieve these stresses in panels with high width to thickness ratios, material buckles out of plane producing the characteristic waviness of oil canning. The stresses may be introduced at a number of stages in panel manufacturing.

- Metal Coil Production

All fabricated metal roof and wall products begin in “coil” form. Coil is produced in a rolling process under pressure to create very thin strips which are then “coiled” for ease in handling. Stresses induced during coil production may contribute to oil canning. Examples of these types of stresses are:

Full Center – Coil is longer in the middle of the strip which creates ripples of buckles near the mid-coil area

Wavy Edge – Coil is longer along the edge of the strip.

Camber – Coil deviation of a side edge from a straight line.

These conditions exist to some extent in all light gauge flat rolled metal coil and tend to become more exaggerated as the material tensile strength increases. Thinner material and dimensionally wider coil are also more prone to oil canning than thicker, narrower coil.

- Coil Processing and Panel Fabrication

Slitting – Generally several narrower coils are cut by slitting from a single (wider) master coil. The economies of producing wider coils makes this secondary process a common proactive. Slitting of a matter coil can release and redistribute residual forces. This redistribution of stresses can increase the occurrence of oil canning within the final product.

Forming – Stresses are introduced during forming of either roof or wall panels. Architectural panel profiles typically require more forming along the edges than in the middle of the sheet. This often necessitates more forming and bending along one side than the other and the stresses produced are not symmetrical within the sheet. Formed panel profiles require “working (bending)” of the sheet. Bending occurs along the edges and there is a tendency to “trap” uneven stresses within the center portion of the finished profile, producing oil canning. In contrast to flat, architectural profiles, corrugated ribbed profiles are most often roll formed from the center and moving outward, thereby “pushing” the differential stresses to the edges of the sheet.

Forming sheet metal inherently introduce stresses to the material. Equipment tooling, setup and operation can minimize these stresses. Proper feed rate, tooling maintenance, proper tooling design, and proper adjustment of the equipment will minimize the differential stresses that cause oil canning.

3.Support Systems and Substrate Suitability

Misalignment of the Support System – If the structural supports or perimeter framing system of a roof or wall panel system are not flat, “non-planar” or contoured, additional stresses can be induced into the sheet as the panels are forced to conform to this uneven surface. This can be the case even when the support structure is produced, fabricated, and installed within allowable industry tolerances.

Movement of the Primary Structure – If the primary structure moves due to differential deflection, racking, drift, settlement or other causes oil canning can occur as the panels are forced to confirm to this movement. This oil canning is sometimes temporary as the support system continues to move but could permanent depending on the cause of the movement.

Camber – Commercial support structural elements such as roof rafters and trusses are often designed with an intentional bow or camber, anticipating deflection under load. If the rafter, truss, or joist is fabricated with camber (crowing at mid-span) it produces a contoured substrate that can induce oil canning of the finished surface at installation or after a load is imposed.

4.Panel Installation

Over-Engagement of Panels (Roof Panels) – Roof panels are designed to a specific coverage dimension and accommodate transverse thermal expansion by flexing the rib and seam areas of side joints. When panels are not installed true to the intended coverage dimensions, these relief features can be minimized or eliminated altogether. In the extreme case, the over engagement process itself can generate oil canning within the flat areas of the panel.

Improper Installation (Wall Panels) – Wall panels are generally designed to a specific coverage dimension and to accommodate thermal expansion. Panels often do this by expanding/contracting at the joints located between the panels. Panels can be designed with slotted connections or extrusions that slide across each other to accommodate this movements. When panel joints are not designed or located properly, stress relief cannot take place and oil canning can be the result.

Over Driving of Fasteners – This installation error can create stresses in the panel and can cause visible oil canning along fastener lines.

Thermal Expansion – Due to the profile of panels, longitudinal expansion is generally the primary concern. Any expansion across the width of the panel is generally taken up at the raised portion of each profile. The surface temperature of exposed panels cycles through the year and even fluctuates daily. The range and cycle depend on many variables (e.g., project location and building orientation, cloud cover, surface finish or color, solar absorption characteristics, etc.).

As the panel surface temperature fluctuates, panels expand or contract. Surface temperature may be more than 100 degrees higher than ambient air temperature. Fasteners, clips and perimeter connections should be designed and installed to accommodate the anticipated thermal movement of the panel. If panel expansion/contraction is inhibited by perimeter flashing conditions or inadvertent “dual pinning” at other details, the result can be seen as oil canning. Waviness caused by thermal forces differs from the other form of oil canning in that waves can appear and disappear daily as the panel temperature varies due to solar absorption or radiation.

Improper Storage & Handling – For certain types of metal panels, storing or carrying panels in a flat orientation, twisting, or buckling panels can induce a wavy appearance to a previously flat panel. Twisting can occur if one corner of a panel is used to lift a panel or to remove the panel from a bundle or pallet. Manufactures’ recommendations should be followed.

How Can Oil Canning Be Minimized?

Certain designers regard oil canning as inherent to the material and treat it as a desired effect accentuating the materials natural characteristic, while others do not. Coil producers and panel manufacturers general attempt to minimize unintentional non-flat conditions. Research continues on improved production and fabrication methods. While a number of factors are involved in panel design, there are steps that the project designer, panel manufacturer, panel fabricator and installer can take to reduce the probability, severity and visual impact of oil canning.

Coil – Tension (“stretch” or in line) precision leveling is a process that stretches the metal beyond the yield point while the metal is in coil form. Once stretched to this point, the metal will not creep back to its previous non-level state. This provides a flatter surface less prone to oil canning and may correct inconsistencies of coil production and secondary coil operations. For this reason, tension leveling should be done after secondary operations such as slitting. The effect of oil canning can be reduced by ordering tension leveled material.

Gauge – In general, the thicker the metal (the small the gauge number) the less likely a panel is to oil can.

Panel Design – In general, the use of attachment systems that allow panels to move without inducing thermal stresses is another mean of controlling oil canning. The addition of stiffening ribs in the panel profile “break up” the flat surface and may make oil canning less apparent but may also add minor shadow lines.

Panel Finish – The eye perceives reflection of light, which is why oil canning on a lower gloss surface is less perceptible than a high glass surface. Low glass finish systems or embossed surfaces, which are less reflective, may reduce the visual perception of oil canning seen in the metal.

There is less difference in the appearance of reflected light from a lighter color panel with oil canning than from a darker color panel, which makes oil canning more noticeable on darker colored panels.

Installation Issues – Stringent specifications regarding the alignment of the support structure or the deck would focus attention on this critical aspect. Normal trade practices and tolerances concerning the tolerances concerning the substrate may not be adequate to minimize oil canning of the finished surface. Manufacturer recommendations regarding proper handling, spacing, and fastening of panels should be part of the manufacturer’s installation recommendations.

Use of Backer Rod or Other Similar Shimming Materials – Some designers specify the use of “backer rod” or other similar types of shimming materials on the panel underside when installation is over a solid substrate. Backer rod is a compressible foam strip normally used in the concrete and masonry trades in joints to serve as backing for a caulk joint. For certain types of metal panel systems, it causes the center of the panel to “pillow” uniformly, relieving stress and reducing the visual effects of oil canning.

Concluding Remarks

Many uncontrollable factors contribute to oil-canning and no panel manufacturer, fabricator or installer can assure the total prevention of oil canning on any given project. With careful attention to the production, material selection, panel design and installation practice, the tendency for oil canning can be minimized.

If oil canning is caused by external factors, such as detailed in “Support Systems” and “Substrate Suitability”, even replacing panels may be ineffective if the root cause is not addressed.

Oil canning is generally an aesthetic issue. Structurally integrity is typically not affected. In the absence of specific contract requirements, oil canning should not be the soul grounds for panel rejection.