Classic Rib

Color Options

*Please contact us for more info and color options.

FL #

Model, Number or Name

Desciption

Limits of Use

Certifications

14645.5

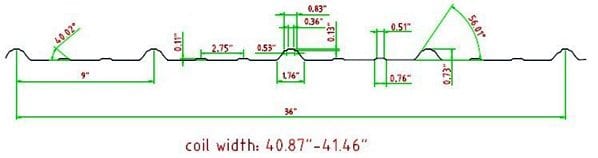

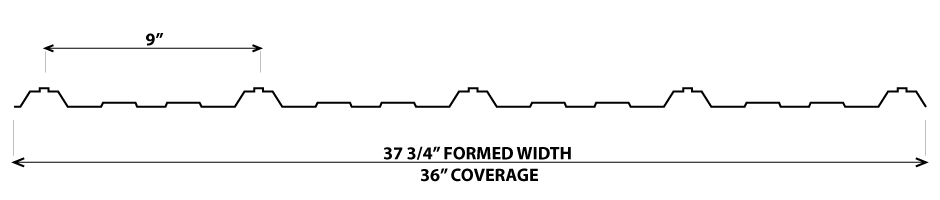

Aluminum Classic Rib

Nom. 0.032″ thick, 36″ wide, aluminum through fastened roof panel over min. 15/32” thick plywood deck or 7/16″ thick OSB.

Approved for use in HVHZ: No

Approved for use outside HVHZ: Yes

Impact Resistant: N/A

Design Pressure:+N/A/-120

Other:Uplift load of 30 psf at fastener spacing of 36″ o.c. and 120 psf at fastener spacing of 6″

o.c.

Approved for use outside HVHZ: Yes

Impact Resistant: N/A

Design Pressure:+N/A/-120

Other:Uplift load of 30 psf at fastener spacing of 36″ o.c. and 120 psf at fastener spacing of 6″

o.c.

Installation Instructions for FL14645.5 – Aluminum Classic Rib

Verified By: Bala Sockalingam PE 62240

Created by Independent Third Party : Yes

Evaluation Reports : Yes

Evaluation Reports for FL14645.5 – Armour 5-V Crimp 0.032″ Aluminum

Created by Independent Third Party:Yes

Verified By: Bala Sockalingam PE 62240

Created by Independent Third Party : Yes

Evaluation Reports : Yes

Evaluation Reports for FL14645.5 – Armour 5-V Crimp 0.032″ Aluminum

Created by Independent Third Party:Yes